MEGA-1 Series Pre-Cooling Air Handling Unit

The MEGA-1 Series Air Handling Units manufactured by Shinwa Industrial Co., Ltd. are specifically designed for systems requiring higher static pressure and longer duct runs. These units are particularly well suited for fresh air pre-cooling applications. Hoisting, installation, and on-site construction are simple and convenient.

Product Features

Coil:

Equipped with a Japanese original imported 3/8" seamless copper tube aluminum fin heat exchanger, precision mechanically expanded to ensure perfect bonding between aluminum fins and copper tubes for optimal heat exchange efficiency. Each coil undergoes 100% submerged air-tightness testing at 25 kg/cm² in accordance with the ISO quality assurance system, ensuring reliable and guaranteed quality.

Drain Pan:

Formed from SUS stainless steel, offering excellent corrosion resistance, oxidation resistance, and maximum service life. The drain pan is insulated with 10 mm thick high-density PE insulation board, eliminating the risk of water leakage, condensation, or dripping.

Quality Assurance:

Shinwa’s MEGA-1 slim-type air handling units can be selected from the catalog to meet specific design and application requirements. For pre-cooling or air-conditioning applications in smaller spaces, these units can fully replace conventional Air Handling Units (AHUs), resulting in significant cost savings. All units in the series undergo 100% performance and operational testing prior to shipment, ensuring dependable and trustworthy quality.

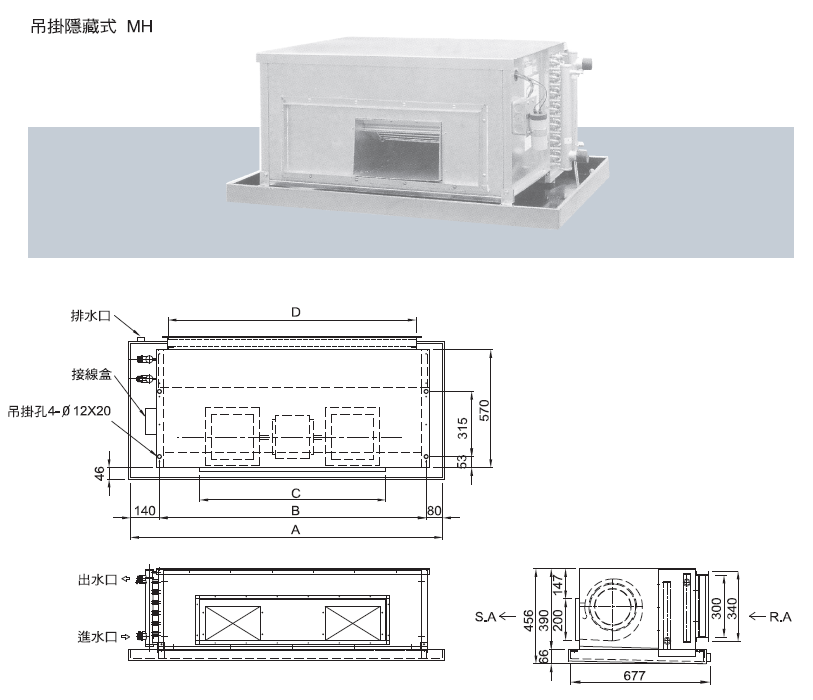

Compact Size / Low Profile:All suspended models have an overall height of only 456 mm. The ultra-slim and compact design eliminates the need for large installation clearance typically required by conventional AHUs, making installation easy in virtually any location.

Quiet Aluminum Fan Wheel:The entire series uses original Japanese imported, high-quality fan wheels. Aluminum fan blades provide excellent corrosion resistance and ensure long-term operation without deformation. The result is ultra-quiet operation with low power consumption and reliable performance.

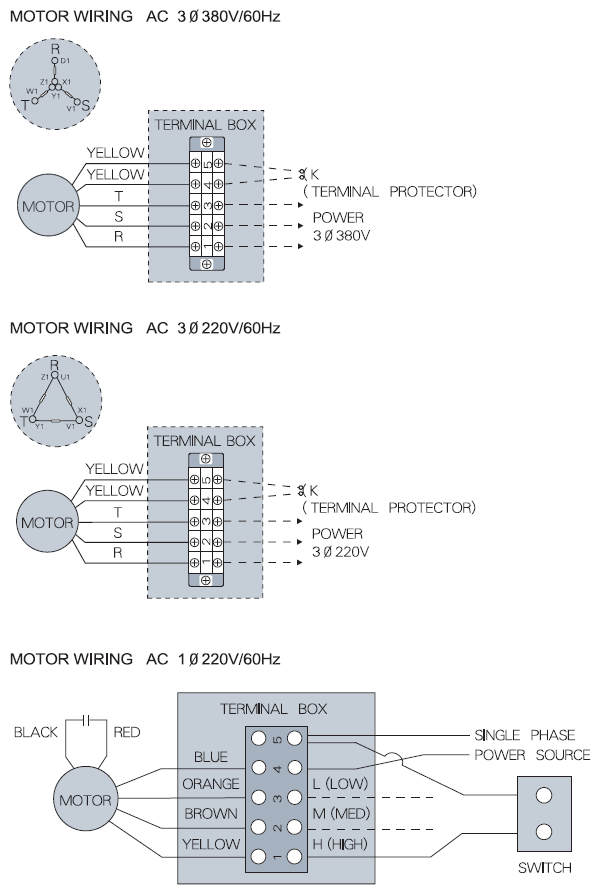

Direct-Drive Motor – Safe, Energy-Efficient, Long Life:All models utilize direct-drive, oil-impregnated ball bearing motors that require no lubrication or maintenance. Operation is smooth, quiet, energy-efficient, and low in vibration. To comply with increasingly stringent electrical safety regulations, single-phase capacitor-start models use split-phase capacitors enclosed in metal housings with protective covers, securely mounted to the unit casing to ensure maximum operational safety.

Heat Exchange Aluminum Fins:Shinwa’s standardized coil aluminum fins feature a slit-type design that promotes smooth airflow and maximizes heat exchange efficiency. (Optional corrosion-resistant aluminum fins are available upon request, offering enhanced protection against corrosive substances.)

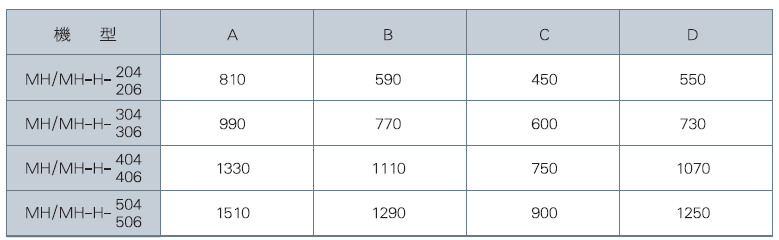

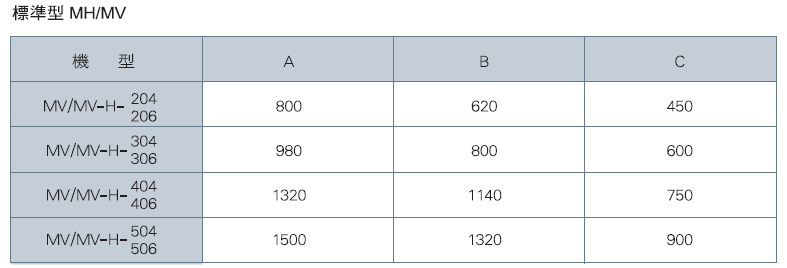

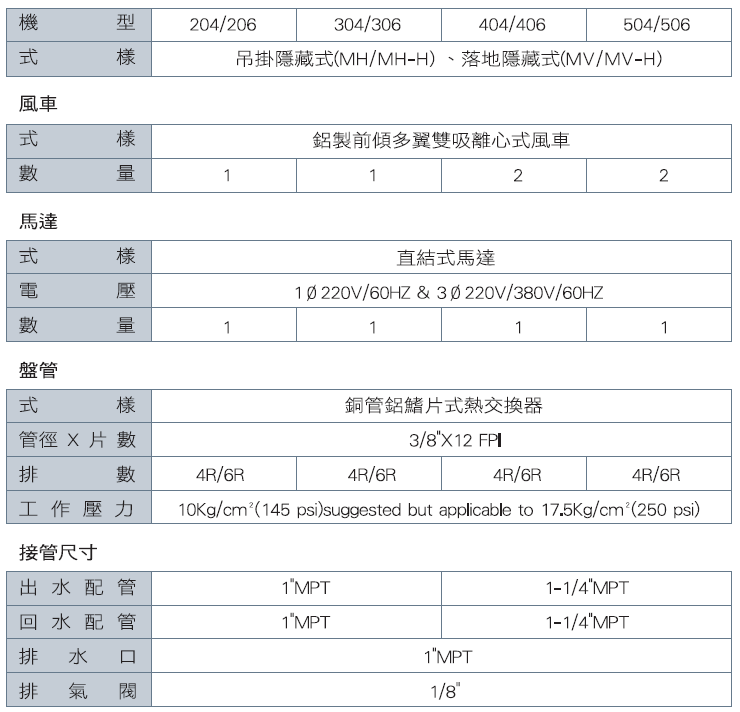

Product Model

Motor Wiring Diagram

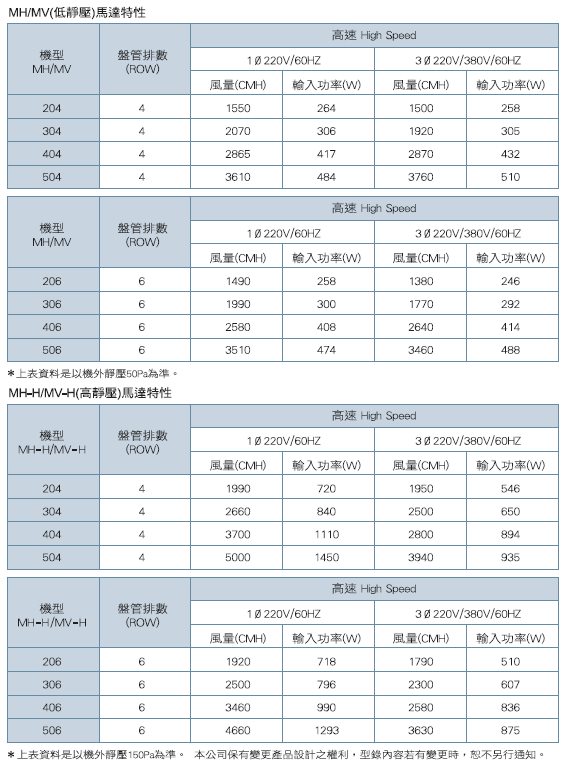

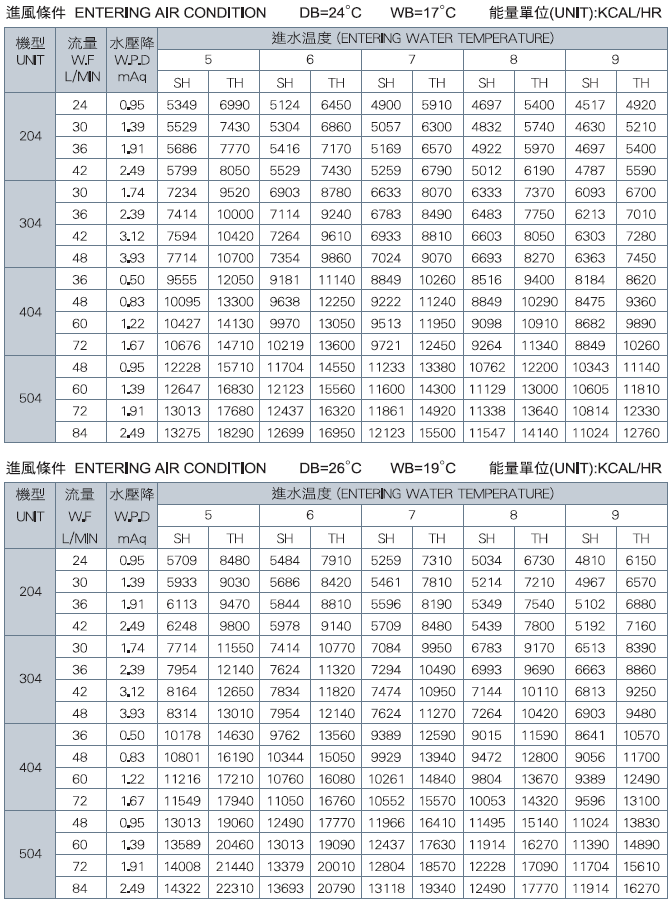

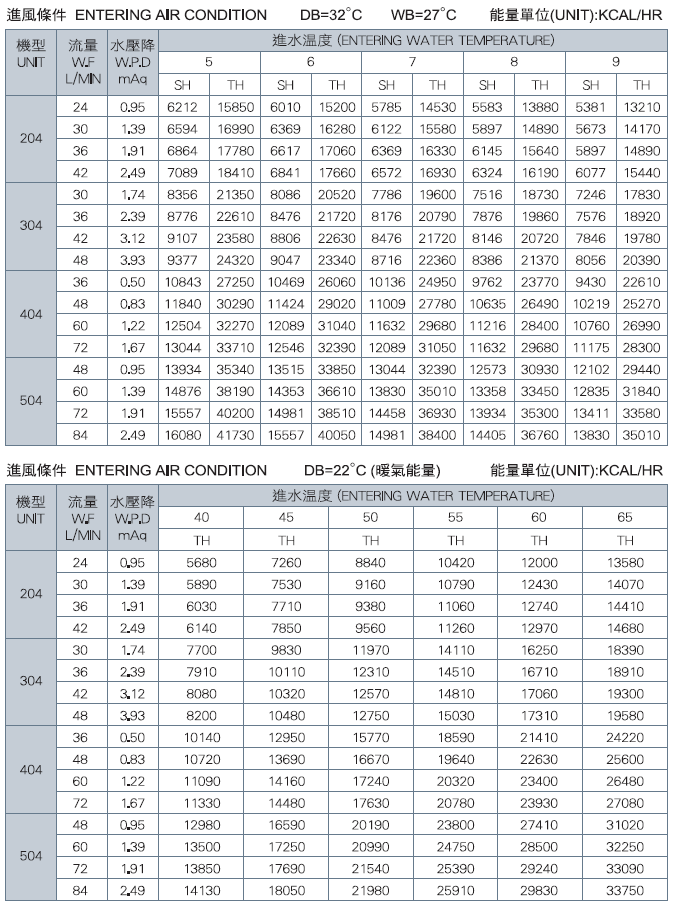

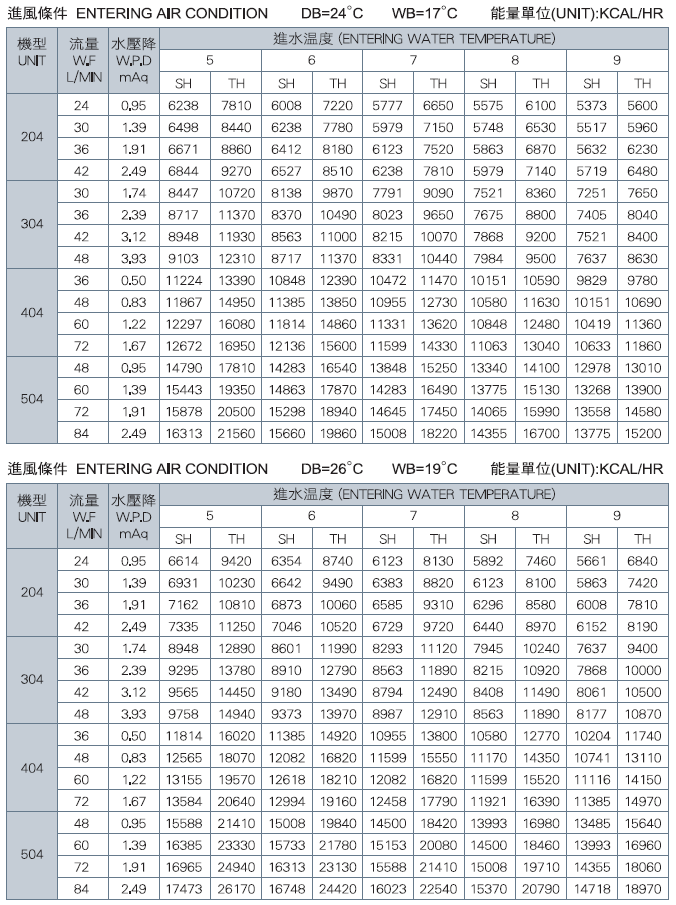

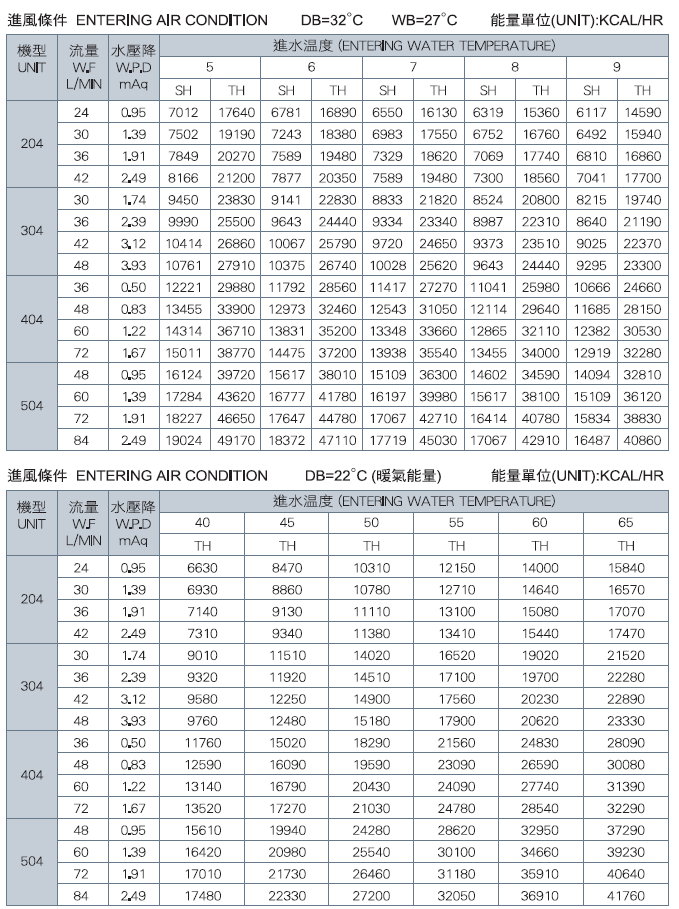

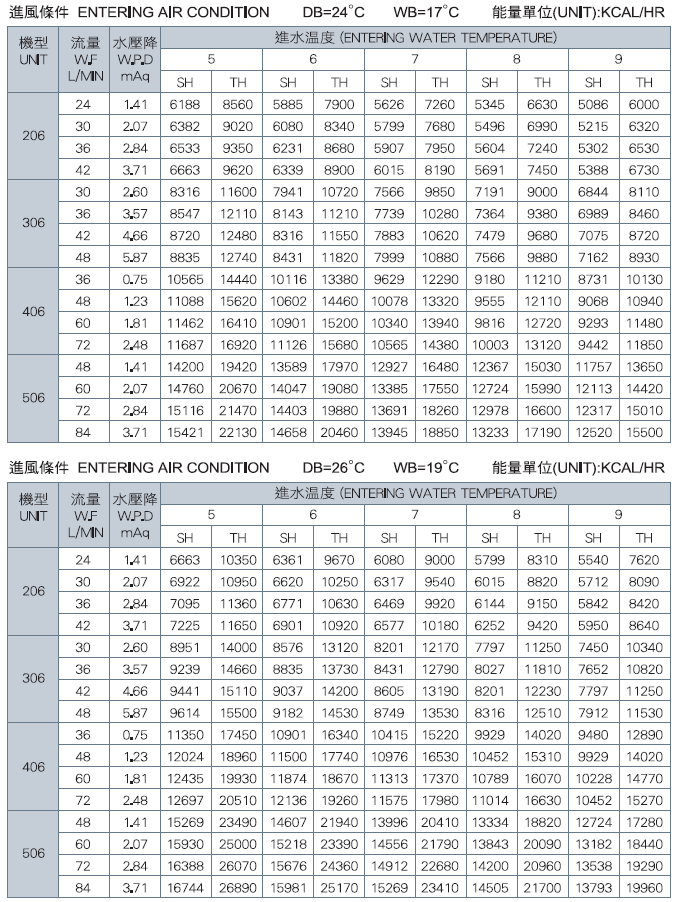

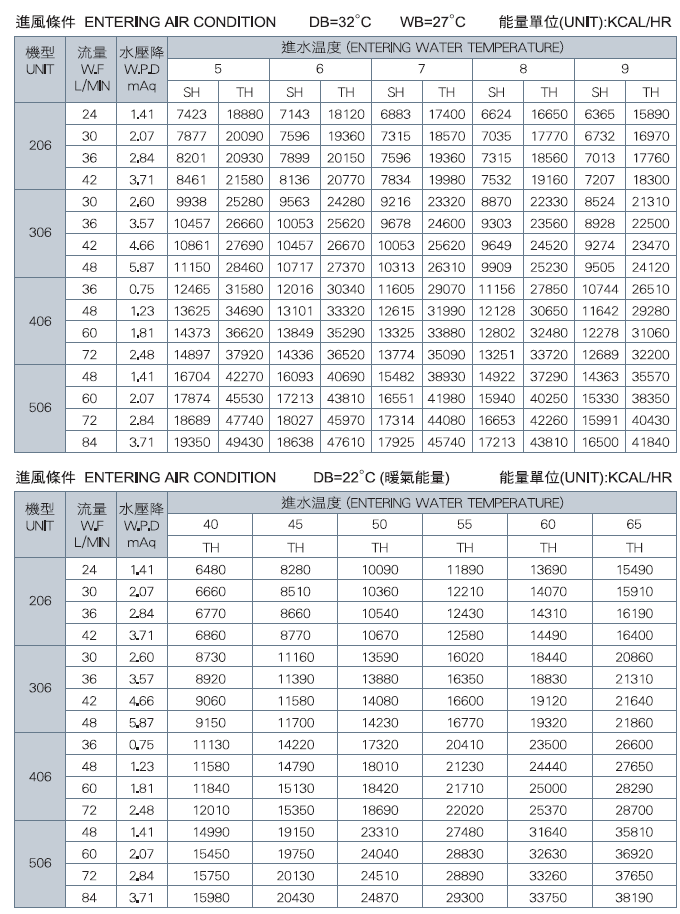

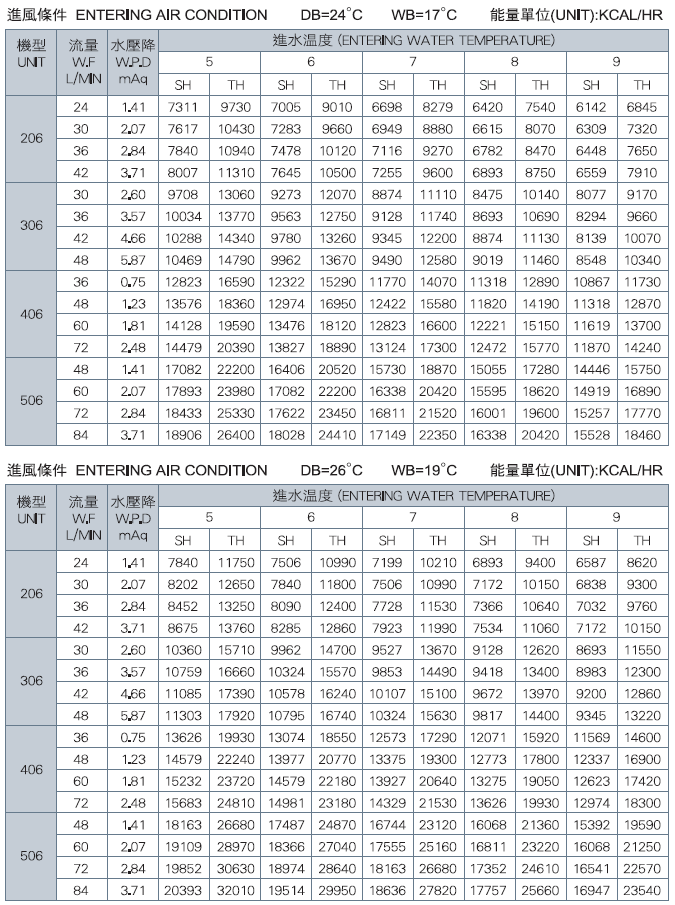

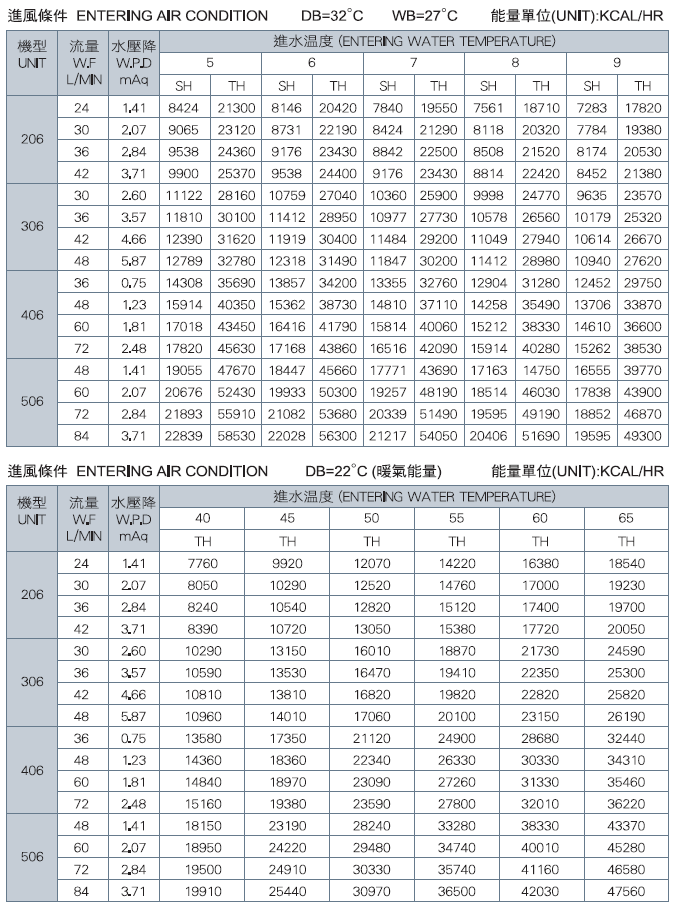

Specification Table

*The data in the above table are based on an ESP of 50 Pa. Sensible Capacity (kcal/hr) – SH,Total Capacity (kcal/hr) – TH.

*The data in the above table are based on an ESP of 50 Pa. Sensible Capacity (kcal/hr) – SH,Total Capacity (kcal/hr) – TH.

*The data in the above table are based on an ESP of 150 Pa. Sensible Capacity (kcal/hr) – SH,Total Capacity (kcal/hr) – TH.

*The data in the above table are based on an ESP of 150 Pa. Sensible Capacity (kcal/hr) – SH,Total Capacity (kcal/hr) – TH.

*The data in the above table are based on an ESP of 50 Pa. Sensible Capacity (kcal/hr) – SH,Total Capacity (kcal/hr) – TH.

*The data in the above table are based on an ESP of 50 Pa. Sensible Capacity (kcal/hr) – SH,Total Capacity (kcal/hr) – TH.

*The data in the above table are based on an ESP of 150 Pa. Sensible Capacity (kcal/hr) – SH,Total Capacity (kcal/hr) – TH.

*The data in the above table are based on an ESP of 150 Pa. Sensible Capacity (kcal/hr) – SH,Total Capacity (kcal/hr) – TH.

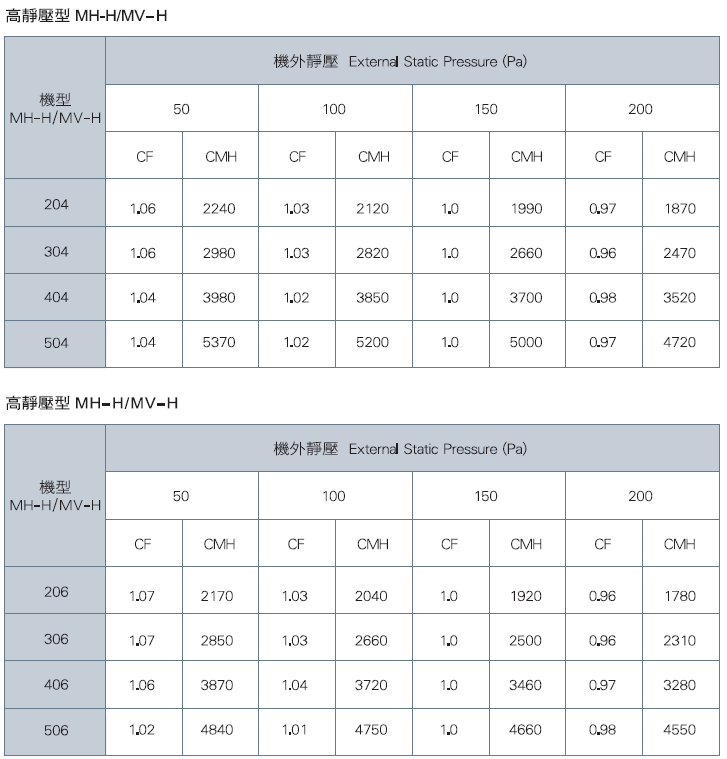

Energy Correction Factor Table

*The data in the above table are based on the 1Ø 220V model operating at an external static pressure of 150 Pa, with the energy correction factor set to CF = 1.0.